Quote demand

Mineração

Mineração

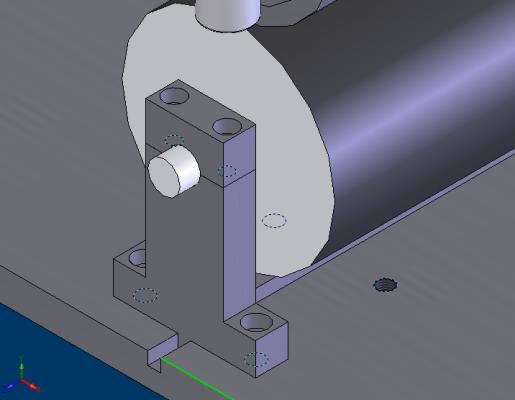

STRAIGHT RETURN ROLLER SUPPORT WITH QUICK EXCHANGE FOR CONVEYOR BELTS – 1

These videos are examples of types of conveyor belts and their respective equipment, with which we can work depending on the customer’s need and the demanded conveyor belt design. Synchronized belts are best suited for longer life.

Talk to our engineers about any lingering doubts about projects that require conveyor belts, we would love to know more about your company to better assist you.

STRAIGHT RETURN ROLLER SUPPORT WITH QUICK EXCHANGE FOR CONVEYOR BELTS – 2

Viga has more than 40 years of experience in the field of equipment for mining and other metalworking services for various sectors.

Whoever owns a business knows that any problem can be very impacting on production costs, making profit a lot. That is why it is important to have experience, good materials and a project that is appropriate to the environment of use. Do not risk closing another deal before talking to us! ;-)

Suporte Porta Rolo de Carga Auto Alinhante para Correias Transportadoras Industriais

Suporte Porta Rolo de Retorno Auto Alinhante c/ Troca Rápida p/ Correias

Suporte Porta Rolo de Retorno para Correias em V com Troca Rápida para Correias

Depending on the function of the conveyor belt component, there are several means of categorizing it. With regard to the support, for example, there are two elements of great importance in a system of conveyor belts for the industry.

Support for Industrial Belt Conveyor Belts

All the components responsible for the support of the conveyor belt fit as supporting structures. The good planning and execution of a conveyor belt project depend essentially on this structural group, since it must take into account the full weight on it, not only that of the industrial belt itself but also of the elements that it will carry. Variations or slopes of the relief where the industrial treadmill will be installed should be taken into account at the time of the quality tests of this industrial equipment, as well as the types of loads to be worked.

Many companies that use industrial conveyors do not research enough about the quality of the conveyor support structure to be purchased. However, despite the market’s lack of attention to this part, it is extremely important, not only to guarantee the operation of the industrial equipment as a whole but also to extend the life of the other components. Industrial belts in disarray, tend to force bearings and other moving components, consuming them in advance, through the heat generated in the friction.

Drive drum for connection between the motor and the belt

The Drive Belt of the industrial conveyor belt is what transmits movement to the rolling system by means of connection between the motor and the belt. It is essential that the conveyor belt is of a good quality, that it can withstand all the tension applied to it and prevents sliding on the drive drum or the motor pulley, which would compromise the power of the conveyor belt by wearing it in advance, including breaking the conveyor.