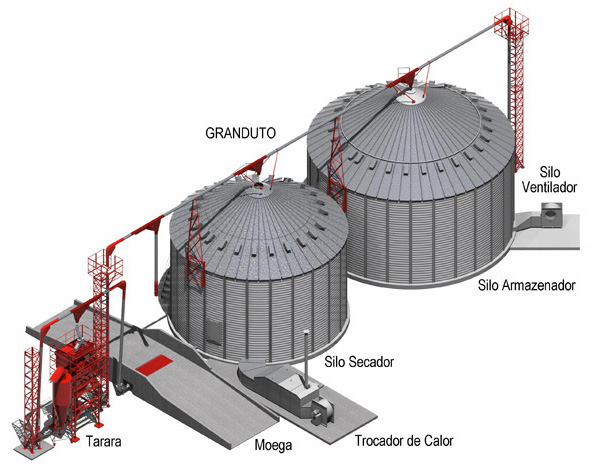

Aerial metallic silos

Our overhead metal silo is coated with special materials that protect it from oxidation and increase the useful life of stock material. Therefore, it presents minimum losses, of a maximum of 5%, when the grains of the silo are harvested and kept in good condition.

For these reasons, if you want to maintain a high productivity rural property, the steel silo is recommended for your venture.

There are several types of a silo. Currently, we have had a greater demand for aerial metal silos. For this, depending on the type of grain, special materials are required for the manufacture of a silo. At the same time, Viga produces a silo for corn, silo for beans and silos for grains in general. Contact us to find out more about our silo designs.

Other types of silo

Half-slope cylindrical silo

Half-slope cylindrical silo picture

The half-sloped cylindrical silos, covered Greely by tile, are designed to be next to slopes, which simplifies the loading for later distribution. In this type of silo, the compaction of content is usually done by human labour and access to the top can be complex, although its filling is facilitated.

To facilitate removal of silage from the silo, side windows should compose the design of the silo, which also aids in ventilation for the worker responsible for compaction.

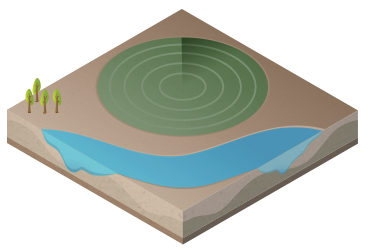

Cylindrical silo type cistern or well

Cylindrical silo type cistern picture

This type of Silo allows greater ease to fill it because it does not need ascent to reach the top. It is also possible to install it near the place of production or unloading, which facilitates the usual processes of filling and unloading the silage.

The compaction of the cylinder-type cylindrical silo is, like the cylindrical half-slope silo, made by workers, without great complexity. But its unloading can be laborious because it requires at least two employees (one inside and the other outside) using a system of ropes with pulleys and balloons.

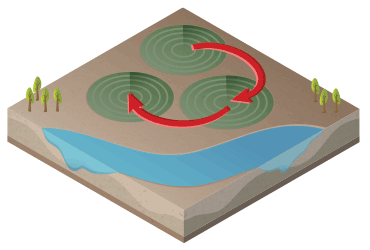

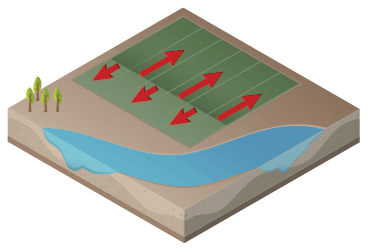

Trench or horizontal type trench

Trench or horizontal type trench picture

As its name says (trench silo), it is entrenched in the ground, forming a trapezoidal prism, being, therefore, the most used, because it has a wide entrance area, which allows easy loading, silage compaction and unloading.

The cost of building the trench type silo is generally lower than other types of a silo, as there is no need for support since it will be buried in the ground. However, it is necessary to pay attention to the terrain on which it will be implemented because if it is too humid it can shorten the useful life of this silo project.

Surface silo

Surface silo picture

The surface silo is the least costly to make because, in this silo design, there is no need for coatings or masonry. The surface silo does not have a strict definition for the shape of the end areas, but it looks very much like the trapezoidal silo.

This silo design basically consists of compaction of the silage in trapezoid format, which should be covered by tarpaulin or other material resistant to rain and other weather. Finally, in order for the cover to be secured, the land is thrown on the edges of the cover, so that it does not fly and remains stuck to its goal.

Avaliações

Não há avaliações ainda.