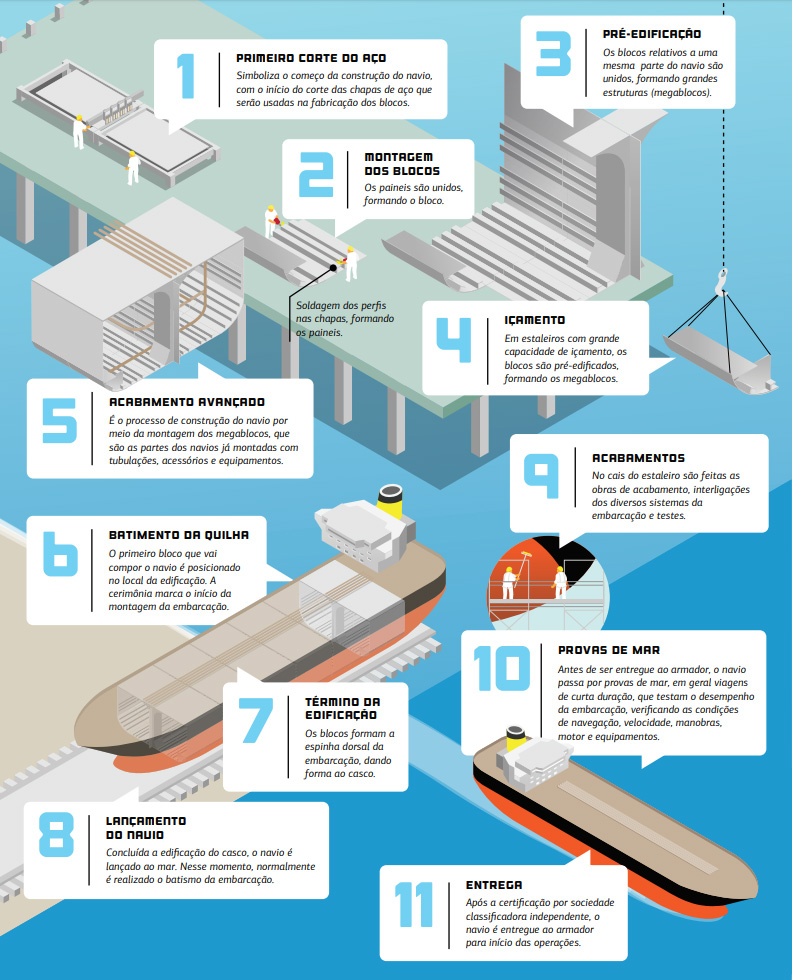

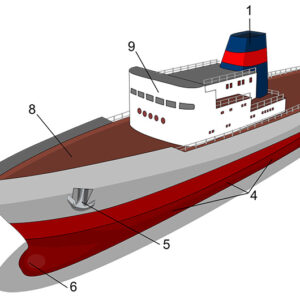

How a ship is made

First Cut of Steel

The initial metal sheet cut is where, actually, the fabrication of a ship begins. These plates are used for the manufacture of naval blocks

Assembly of naval blocks

At this stage, the naval blocks are assembled by means of the steel plates initially cut

Pre-building of naval blocks

The naval blocks of each part of the ship are assembled, forming the naval mega blocks, which represent large structures

The lifting of naval mega blocks

Using super powerful cranes, the mega blocks are raised, forming even larger blocks, this stage is a continuation, still, of the edification

Advanced finishing

With the pipes, accessories, equipment and electrical part already in its due naval blocks. These are joined to one another, already being possible to see a ship forming

Keel tapping

Now with the parts representing a whole bay, they will be placed next to the sea for the descent of the ship

End of Building

Being responsible for forming the hull the blocks of the ship’s backbone are already in their final positions and ready for completion

Ship Launch

The construction of the ship is complete and this can be launched into the sea. Normally, it is at this stage that the baptism of the ship is carried out

Finishing off the new ship

Internal finishing works, system interconnections and tests are done in this step

Sea trials of manufactured ship

Sea trials are made before the ship is delivered to the contractor. In general, these tests represent short trips, of short duration, in which several parameters related to the performance of the ship and navigation are verified

Ship delivery

After being certified by an independent body to the construction company, the ship is ready to start operations. It is, then, delivered to the contractor

Avaliações

Não há avaliações ainda.