Types of gantry

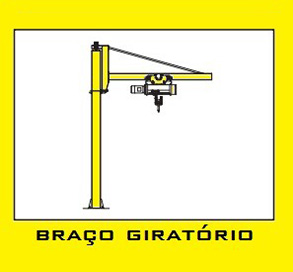

Mobile gantry and semi-gantry

The gantry can be a rolling porch or a semi-gantry, the first, is not hit the wall, having wide mobility, the second is already attached to a support column and allows coverage of only 180 degrees. Both gantry projects are run by Viga, talk to our engineers and learn a little more about how we can help you achieve greater productivity in your industry.

Mobile gantry

There are several types of equipment for load handling and lifting. Among these, the manual mobile gantry is very suitable to compose the factory floor in order to facilitate the manufacture of industrial equipment, as it allows great agility in production, smoothing the operational work of the employees.

Among the parts of the movable gantry that deserve to be highlighted in a manufacturing project, the rotary castors are usually the most remembered as possible to have their material customized since they can be of nylon, cast iron or coated with polyurethane.

Another part that composes the rolling gantry is the carving, that has a small motor, if it is electric, or not, being manual. The electric hoist usually uses a chain to make the lifting of the load.

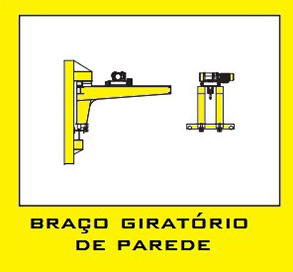

Semi-gantry

The semi-gantry is more used in cases in which the layout does not demand the whole area of the nave in the manufacturing process, being able to use a more restricted space.

In the case of these types of gantry, it is thought that it does not allow a 360-degree rotation unless it is attached to a tower. However, most of the time, in this porch design, it is attached to the wall, having a range of only 180 degrees. Therefore, it is called semi gantry to this model, widely used in several industries.

It is worth remembering that in the mobile and semi-gantry there are several components that can be installed as optional or compulsory to operate, among them we can mention electric hoist or manual hoist, which can be bought from different brands.

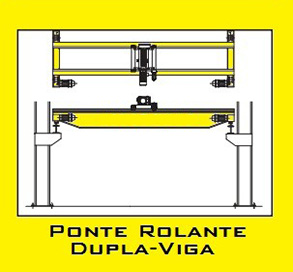

Double girder gantry and single beam gantry

Double girder gantry is indicated for continuous use of industries that demand heavier processes in the manufacture of their equipment. The single beam gantry is recommended for industries that require intermittent and lighter processes. They can be furniture or wall-mounted. The porch can be a manual porch or a motorized porch. Talk to our engineers about your gantry project, we can certainly help!

Double girder gantry

With a carriage mounted on the load beams, the double girder gantry allows great agility in the production of industrial equipment with more smoothness to the employees of the factory floor, as it is developed to meet long paths with the ease of not requiring columns and path of rolling.

The structure of the double girder gantry can be tubular or of metallic ducts and the electrical system allows customization, however, it is generally used longitudinally in the power supply.

As the double girder mobile gantry has great mobility and resistance, this crane model can be used in many different types of projects, from non-perennial use, classified as maintenance porches to gantry projects of continuous use.

Single beam gantry

Because it has only one hoist support beam, manual or electric, this type of gantry is generally used in industries with processes that require not-so-heavy lifting and not so frequent because it distributes the lifting load in only one support structure. Another limiting factor of this gantry model is the mobility distances, which, too, can not be very wide between the rails, called gantry span, or spacing.

Like the other gantry models, the electrification is longitudinal and the hoisting system itself is called hoisting, which can be either manual or electric. The electrical, as already mentioned, is often composed of steel chains that must be resistant to the load to be hoisted. Predictive maintenance is recommended to avoid accidents on the factory floor.

Avaliações

Não há avaliações ainda.