Mini-course on maintenance of industrial conveyor belts

Understand better factors that should be taken into account when manufacturing your industrial conveyor belt design:

- Types of conveyor belts

- Safety on conveyor belts

- Signs and standards of the conveyor belt

- Individual and collective conveyor belt protection equipment

Types of Belt Conveyor

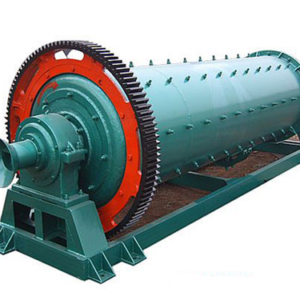

The most common types of belt conveyor for mining found in a mine are:

- flat belts: for pallets and single loads

- concave conveyor belts: for the transport of bulk material

However, belt conveyors can also be used in other industrial areas, as well as:

- Chemical industry: Salts, sulphur, urea, fertilizers, sulphates, etc.

- Food industry – Sugar, salt, flour, cocoa, cereals, etc.

Equipment for Conveyor Belt Conveyor

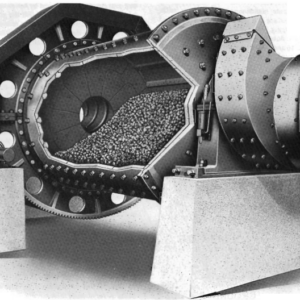

When looking for a concave belt conveyor, it is usually desired to buy all conveyor belt equipment that composes it as a whole, such as:

- rotation sensor

- belt conveyor brake

- conveyor belts rollers

- trestle with strap

- roller support

- rubber for conveyor belt

- emergency keys

- belt misalignment keys

- misalignment sensor for conveyor belt

- hydraulic couplings

- conveyor belt scraper

- rotary brushes

- overflow sensors or level

- air deflectors

- fixed or mobile tripper

Prevent Accident with Conveyor Belt

Due to the misalignment sensor for the conveyor belt, rotation sensor, overflow sensor or level that are coupled in many designs, the safety on conveyor belts manufactured by Viga, according to the NR provided in the design, allow the highest quality in the design. delivery of the final product. Watch the video that portrays the manufacturer’s lack of predictive maintenance or quality that can result in accidents with conveyor belts, do not take that risk.

Avaliações

Não há avaliações ainda.