Vídeos sobre manutenção de correias transportadoras

Exemplo de rolete para correia transportadora fora do centro

Who works in an industry knows well that the elevated costs on transports while manufacturing the product, that is going to be sold, will eventually lead to reduced company profits. Due that, is extremely important that the internal distribution process of raw materials have to be efficient and effective, reducing your manufacturing time and increasing profits.

Types of Conveyor Belts

There are different types of industrial equipment and several others conveyor belts, which are:

- V conveyor belts, that can be found diverse sizes, allow a good performing in small ambient and does not produce loud noises, besides that, a good maintenance is required to avoid loss of performance.

- Synchronized conveyor belts show more agility and lifespan when compared to traditional conveyor belts.

Used conveyor belts?

Several people search about used conveyor belts, but the risk of stopping the production and the cost with maintenance of the used conveyor belt, that will have a lower lifespan, may not worth the investment. That is why we are completely available, with an engineering team specialized in several areas, for answering any of your questions about your conveyor belt project. We would love to know more about details and how we can help you. Request a budget of our industrial conveyor belt right now!

Used conveyor belts can also require a patch. That, with time, can eventually create unexpected moments that we can regret after. Talk to our engineers about that too, we can share experience about conveyor belt maintenance.

Conveyor belt maintenance

It’s very important to pay attention to the lifespan that will require a conveyor belt maintenance, this can be done in a preventive way, befitting the manufacturer terms of use and with the quality of the bought conveyor belt or can be also done after a problem, what is not recommended because can incur risks to the workers and negatively affect profit, specially on a manufacturing profit that is based on low production costs.

When manufacturing a conveyor belt in Viga company, there is a sure that the quality and using instructions that guarantee a better predictability of a conveyor belt maintenance in the case of an unexpected event.

We already produced several long conveyor belts, with kilometers of extension. Don’t take the risk of a mistaken budget on any mining project or any other sector that requires an industrial conveyor belt, talk with us before.

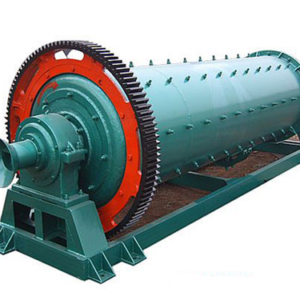

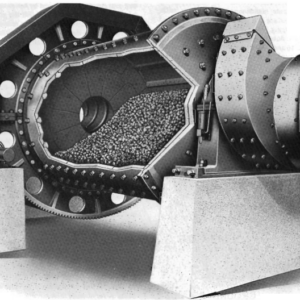

Conveyor belts: rollers

Isn’t rare to ask us about roller for conveyor belts, synchronized belts, V Belts, Rubber Canvas for conveyor belt or Cleated belts. Besides this equipment extremely used on cement industry, cellulose, mining and steel industry, there are other types. However, the biggest demand is always for the rollers, which are one of the most used on industrial transport.

The quality of the conveyor belt roller and its integration should be observed when buying and or while the project development, because one single roller with the wrong size can impact considerably the lifetime of your belt.

Synchronized Belts

Correias sincronizadas são a melhor opção para se evitar o deslize das correias transportadoras pois elas fazem com que este equipamento role por igual em todos os pontos do processo, o que impede o aumento de temperatura por atrito, demandando maior manutenção de correia transportadora.

Synchronized Belts are the best option to avoid the slipping of the conveyor belts, because they assure the equipment running equally in every point of the process, blocking the increase of heat for friction, requiring less maintenance.

Projetos de correia transportadoras e manutenção

PDFs about conveyor belts

Many users came to the website searching about Conveyor belt PDF and that is exactly our intuition for writing about this subject, to be able of creating documents, that can be converted to PDFs about conveyor belts, which can be used as an auxiliary for your conveyor belt project:

- Esteiras industriais e a influência da temperatura

- Manutenção de correias transportadoras devido ao ambiente

- Manutenção preditiva das correias transportadoras e sinais de urgência

- Roletes para Correias transportadoras

- Suporte para correia transportadora

- Cursos e informações sobre correia transportadora

- Correias transportadoras sincronizadas

NN canvas straps

The NN canvas belts are so called because they are composed of two layers of Nylon, which make up both the warp and weft shells, making it stand up to a higher temperature and have good flexibility, as well as good lodging and resistance to wear. In situations that require high shock absorption this type of conveyor belt is most commonly used. Here are some industries that use it:

- Cement, calcination and quarry: Excellent performance in the absorption of impacts

- Fertilizer: Reaction belt – incorporated into the construction of the conveyor belt itself, giving it greater resistance to chemical reactions

- Mining: indicated for the belt of small length that needs to absorb greater impacts

- Paper and cellulose: thorax belt – excellent resistance to impact absorption, and may even have accessories for extreme situations and high severity

- Steel: Belt of the blast furnace – where the high temperature advises against the use of conventional belts (> 150ºC)

PN canvas straps

The PN canvas belts have this name because polyester composes the warp and nylon housing of the weft. What makes it have good flexibility, but not so much as the NN canvas belt, allowing the one to suffer patches, but that does not withstand high temperatures. It is, therefore, a good choice in relation to the cost-benefit, relating some variables in the conveyor belt design to be adopted according to the needs of the demand. Here are some examples of industries that use it:

- Cement, calcination and quarrying: employed in the transport of various materials with a maximum particle size of 150 mm

- Fertilizer: present in all stages of the process except the reaction belt

- Mining: indicated for the transport of materials in medium and long distance with excellent cost x benefit

- Paper and cellulose: present in all stages of the process, except in the thorax belt

- Steel industry: used in the transport of materials with a maximum temperature of 150ºC and in the straps of the patio

Avaliações

Não há avaliações ainda.