What is the flotation column

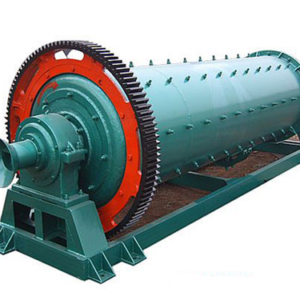

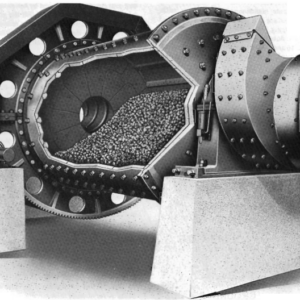

The flotation column is widely used in mining after crushing and milling, steps defined as comminution. In these stages the ore, as the name of the phases itself is assumed, are crushed in smaller pieces. After the comminution, the ore is not yet ready to be used in the final product because it remains impure. That is why it must pass through the flotation column, where, in many cases, starch and oil, which are apolar, are used near the water. The ore, also apolar, will not connect to the water, which represents the densest phase, and therefore, will remain at the bottom. Hence, the ore will float and leave less impure from the flotation column. From there, many will still undergo electrolysis or leaching processes before reaching the final consumer.

Difference between flotation cell and flotation column

Although the flotation column and flotation cell are often treated as the same equipment, the truth is that there is a difference between them. In the flotation column, mechanical devices are necessary to float the mixture, already in the flotation cell, the flotation happens due to aeration. The flotation cell is most commonly used in less dense materials and the flotation column for denser materials. At Viga, we produce both the flotation column and the flotation cell. To know how much we would be able to produce the flotation column or the cell, also called the contact cell, contact us.

Why to produce columns or flotation cells with Viga

Viga has more than 40 years of experience in the field of flotation column manufacturing. We have already developed several metal structures for large companies, not only in the mining area but also in other sectors such as Vale do Rio Doce, Usiminas, Petrobrás and some of the Eike Batista group. We have full capacity to deliver various types of flotation columns.

Avaliações

Não há avaliações ainda.