Mining Industry Concepts

The mining activity refers to the processes and steps performed, industrially, to obtain mineral compounds from the crude sources, coming from them, from oil and natural gas or even water. Mining has a deep importance in maintaining the mould of life and development of modern societies. From construction infrastructures to electronic equipment depends on this important area of extraction and processing, including even cosmetic products.

Here in Viga, a metalworking and steel company, we have strong partners in the mining area, among them: Usiminas, Vale do Rio Doce and Petrobrás. But we also use the raw materials supplied, proudly, from our own customers, for the production of the parts that will serve them and the market. Among our most famous works are various blast furnaces, mining pots, walkways, ships, ferries and other equipment and metal infrastructures.

Quote your demand

The Cominuation in Mining

The mining comminution refers to the breakdown of raw material, in this case, the crude ore, with impurities, in parts of smaller size, that is, it is a process used by mining companies when producing several types of products, which will build, after other stages, buildings, metal structures in general, industrial equipment and small or large infrastructure.

Commitment is the processing of materials to break down rocks and raw material into smaller particles and pieces. This is used in mining and producing a wide range of products including raw materials for construction as well as finished components. Companies can use processes both wet and dry, depending on the materials they work with and how they plan to use them. In this area, research and development work includes the invention of new equipment, better grading systems and new uses for previously wasted materials.

The comminution of ores is a process, in the mining activity, divided into two parts: crushing and grinding.

How Does Crushing Work in Ore Comminution?

Crushing can be considered the first stage of mineral processing, because it is the first transformation of the raw material after extraction, being responsible, as the name says, for transforming larger pieces into brittle. There are several types of crushers, as they are called the mining equipment responsible for this step, the most popular being:

- jaw crusher

- rotating crusher

- cone crusher

- single roller crusher

- rotary crusher

- double roller crusher

- impact crusher

- hammer crusher

How does grinding work?

Being, of course, the step after milling, it is also commonly called fine fragmentation. This stage of the mineral process is responsible, as the name says, for grinding the brittle and further increasing the area of contact of the mineral compound to facilitate future improvements, which will purify the raw ore, converting the raw material into the product, widely used in various market segments, including cosmetics.

In milling, the now brittle ones have their size further reduced by techniques imposed by mining equipment which cause in the raw material post grinding, compression, abrasion, impact and friction, which reduces the product of the previous process , in the case of crushing, to a size conducive to the release of the desired mineral as product, regularly, to be concentrated in the processes to come.

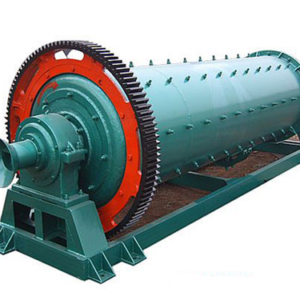

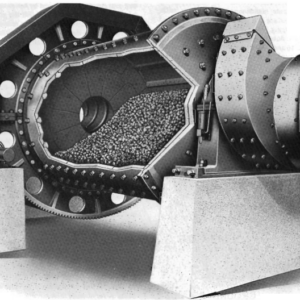

The milling of minerals, practised by the industrial equipment for mining already mentioned, is executed through cylindrical mills (of bars, balls or pebbles) or hammer, which are responsible for the finer grindings, mainly through the friction with the wall of the ore grinder.

Cylindrical ball mills use them as a grinding medium and are used for finer grinding of the ore. Cylindrical bar mills are used for thicker grinding, supporting a feed of up to 50 mm. However, many also consider them as fine crushing machines.

Mineral milling is the most costly stage of comminution, with high costs, varying according to the size of the ore particles resulting from the mineral processing process.

In the area of industrial metalworking, iron ore, which once was a crude mineral coke extracted from nature, is used by Viga in the manufacture of various industrial equipment and infrastructure works. Learn more about this story: