The ship is built piece by piece

The first thing to keep in mind when thinking about shipbuilding is that it represents an end product made up of several smaller parts, known as plates and profiles, or navipeças. In metalworking plants, often already built in the shipyard, the naval parts are produced in the formats defined in the construction project of the ship. Normally, the profiles are made of steel and are welded together to the plates, which cover the dimensions of these, offering them greater resistance.

The ship’s parts are welded forming the naval blocks

Each sheet and profile, after welding one by one, are fitted side by side, forming large naval blocks, which weigh anywhere from 50 to 300 tons and can be of various types. If a naval block is used, for example, to construct the cargo compartment of the ship, it will be empty on the inside and will not present great needs of a refined design, even in the case of a luxury room, the naval block responsible for this environment will provide a more sophisticated design and conditions to suit the ship’s design motifs. The naval blocks, when necessary, had space, according to the design, for the passage of the wires and pipes.

The assembly of the ship with the naval blocks

Once the naval blocks have been completed, it is time to assemble the ship at the shipyard. Each block is raised and aligned, according to the design, by specially developed cranes for this function. After assembling the ship’s ship’s shipyard blocks, the welding points are usually sanded with specialized machines and the naval structure is sandblasted with small balls of steel that remove roughness from the surface. Finally, the ship is painted with anti-corrosion paint.

The assembly order of the naval blocks

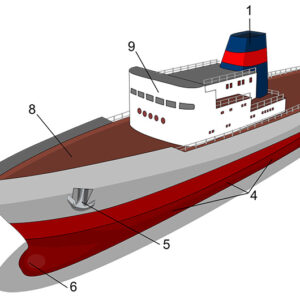

The assembly order of the naval blocks depends on the functionality of each of them. In the case of the engine room, the naval blocks are usually at the back of the ship, allowing a smaller shaft to connect the propeller to the bikes, which would avoid unwanted vibrations in the front of the ship. However, new environmental laws are revising this concept by stating that the ship’s engine, as it is currently designed, disrupts marine life.

Above the engine room, usually stays the machine room, where are the cabins and control rooms. This location of this room is strategic since the loads are generally removed from above, so in the position, just above the engine houses, the house would not disturb the cranes to access the cargo holds.

How is the electrical part of ships?

The electrical part of the ships usually operates by means of diesel-powered generators. The electrical installations are responsible for navigation, pumps, heating and, in the case of multifunctional vessels such as transatlantic, including elevators and swimming pools are available on the ship.

What is the ship’s fuel?

The main ship motors function as a type of special fuel oil called bunker, an oil derivative. Smaller boats uses diesel.

How is the sewage treated from the ship’s toilet?

There are ships up to 300 meters long, like the Panamax. Certainly, the garbage and sewage a ship of these dimensions produces are enormous. Garbage that is not human waste is stored to be dumped in a landfill. Organic human wastes are temporarily stored in special tanks, and then thrown into the sea in accordance with international standards.