Quote your demand

There is two mining equipment used in the purification of the ore by flotation and it is even common to confuse the two as being the same piece. The step of ore processing for the removal of the impurities known as flotation can be done by the flotation column or by the flotation cell.

There is a basic principle governing the operation of two models of flotation equipment in mining: separation of the desired product from impurities by agitation or aeration of the water, where the generally non-ores add to the added oil and impurities, polar, join the water.

Viga has been in the mining business for more than 40 years and knows that the secret of profitability lies in the details of a good industrial metalworking project. That’s why we invite you to continue reading to learn more about the difference between columns and flotation cells before making a decision on where to invest. Also, we would like to talk to you personally, we would love to know more about your company and how we could help you!

Flotation column: how it works

What differentiates the flotation column from the flotation cell, is that the first dispense mechanical devices to stir the contents. In the flotation column, air is introduced into the column by means of spray nozzles, causing bubbles which, on a shaft, called a column, which has dimensions larger than the width, cause a countercurrent which will take care of oil and water, to be the activator of the raw material processing process.

In comparison to the mechanical cells often used, the ore beneficiation process through the flotation columns may be slower but has better kinetics.

Advantages of processing the ore through the flotation column

- Improved metallurgical performance

- Greater control of this mining process

- Reduced power consumption

- Lower need for capital

- Reduced industrial footprint

Contact Cell Flotation in Mining

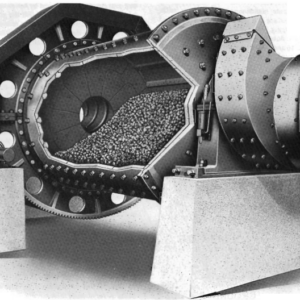

In the case of flotation cells, the aeration of the sludge is done by dispensing with moving parts. This mining equipment has two main components:

The chamber where the sludge containing the feedstock and the floating air is collected under pressure is called a switch. In this log, the pressure is maintained through a restriction that is located at the end of the apparatus at the back of the switch.

- The switch is a chamber in which the feed sludge and the flotation air are collected under pressure. The pressure is maintained by a restriction located at the rear end of the switch.

- In the separation cell, at the bottom, is where the discharging of the interrupt occurs, which went to where the bubble-particle aggregates form foam to be removed containing the already benefited minerals. The particles which are not bonded to the foam are removed by means of an underflow line. As with the flotation column, the foam must be washed in water, which means that the flotation cell can also be used as a cleaning equipment.

This equipment for ore beneficiation is most commonly used in basic flotation at the beginning of the beneficiation process.

Advantages of the flotation cell

Because it is compact, highly efficient and simple to operate, flotation cells have low energy and maintenance costs. There are many other advantages in the use of flotation cells in mining, in particular:

- A considerable decrease of the undulations in the most basic circuit by means of the use of waves

- Improved control foam

- Reduced energy consumption in wastewater treatment plants

- A decrease in capital requirements and operation in cleaner circuits

- Lower maintenance

- A lower amount of basic process control instrumentation

- High potential for energy savings in the basic circuit

- Decreased sampling and flow analysis

- Installed costs and footprint decreased